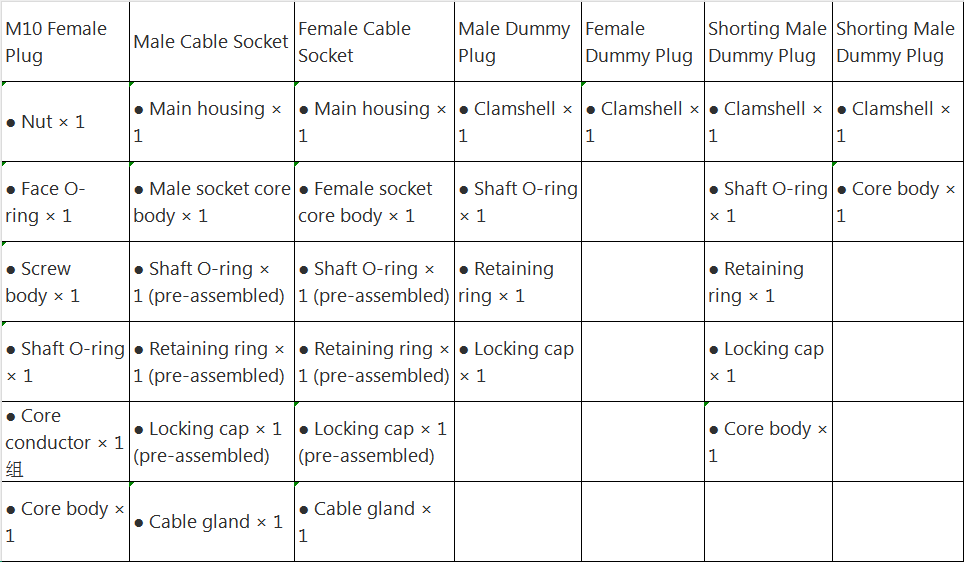

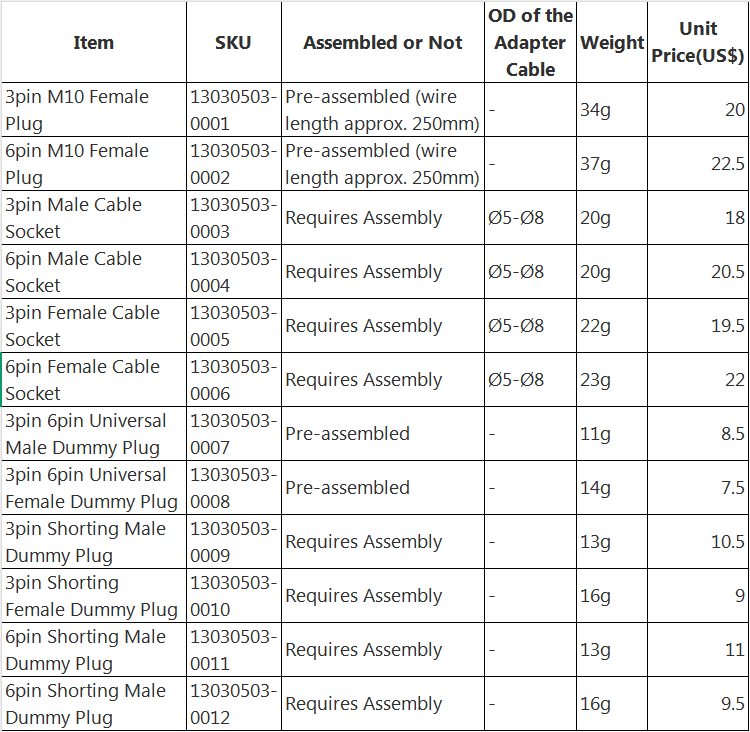

Description

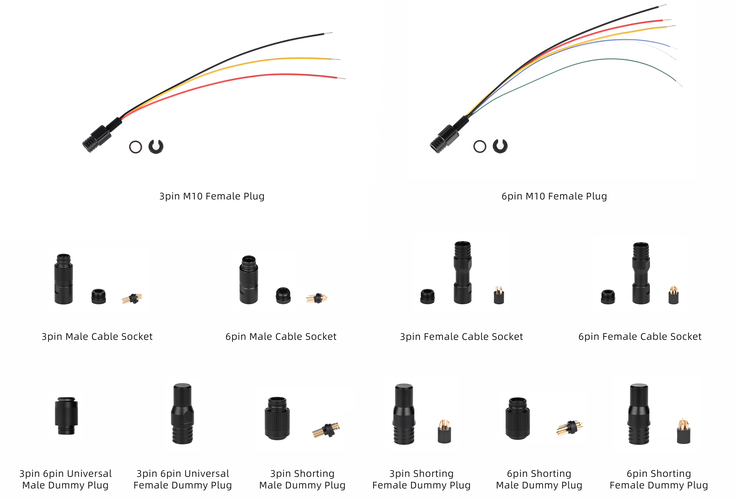

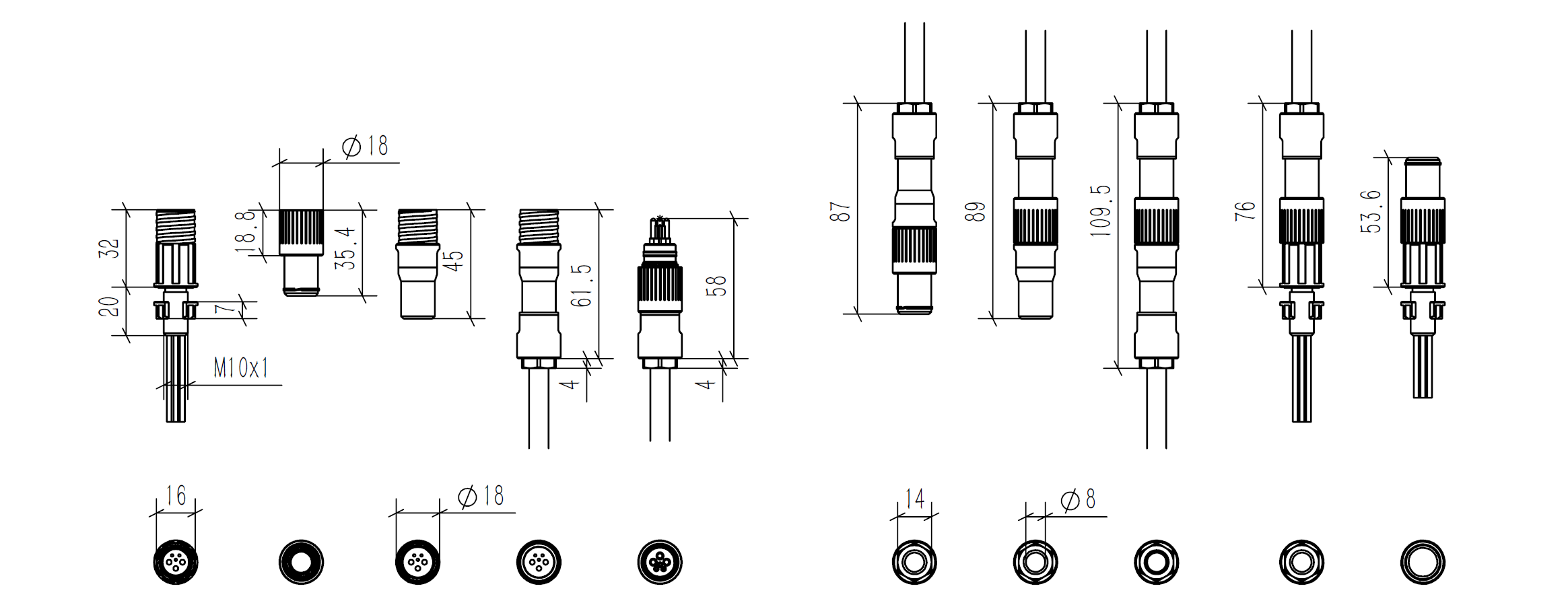

This underwater connector is a dry mate connector designed for use up to 1000 meters deep. It is only suitable for mating in air before immersion in water. The male and female cable sockets need to be assembled with wiring and filled with adhesive, enabling them to be used with various types of cables or components that come with their own cables. The connector is made of hard-anodized aluminum alloy, with gold-plated copper pins capable of connecting power or signal cables. Note that if not mated, connectors must be sealed with plugs for waterproofing. Both 3-pin and 6-pin configurations for female plug male cable socket connectors and line-to-line connections are available, all sharing the same external dimensions.

The maximum outer diameter of both the female plug and line-to-line configurations matches that of other M10 components in SUBLAB, facilitating tight arrangements and interchangeability in bulkhead assemblies.

This underwater connector is a dry mate connector designed for use up to 1000 meters deep. It is only suitable for mating in air before immersion in water. The male and female cable sockets need to be assembled with wiring and filled with adhesive, enabling them to be used with various types of cables or components that come with their own cables. The connector is made of hard-anodized aluminum alloy, with gold-plated copper pins capable of connecting power or signal cables. Note that if not mated, connectors must be sealed with plugs for waterproofing. Both 3-pin and 6-pin configurations for female plug male cable socket connectors and line-to-line connections are available, all sharing the same external dimensions.

The maximum outer diameter of both the female plug and line-to-line configurations matches that of other M10 components in SUBLAB, facilitating tight arrangements and interchangeability in bulkhead assemblies.

Usage of Shorting Dummy Plugs:

The shorting dummy plug has more cores than a regular dummy plug. Depending on requirements, you can solder the ends of the pins, fill them with adhesive, and press them into the locking cap shell. Be careful during shorting to ensure the soldered points do not protrude beyond the outer diameter of the copper pins, preventing contact with the shell.

Dimension:

Recommended mounting holes for female plug:

| Recommended Size | Underwater Connector |

| Recommended Bulkhead Through Hole Size (A) | Ø10.1±0.1 / Threaded |

| Hatch Cover Thickness (B) | 13 |

| Surface Range (C) | 20 |

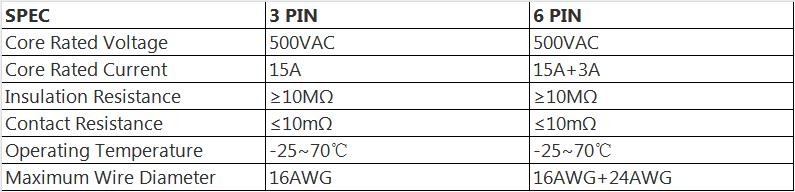

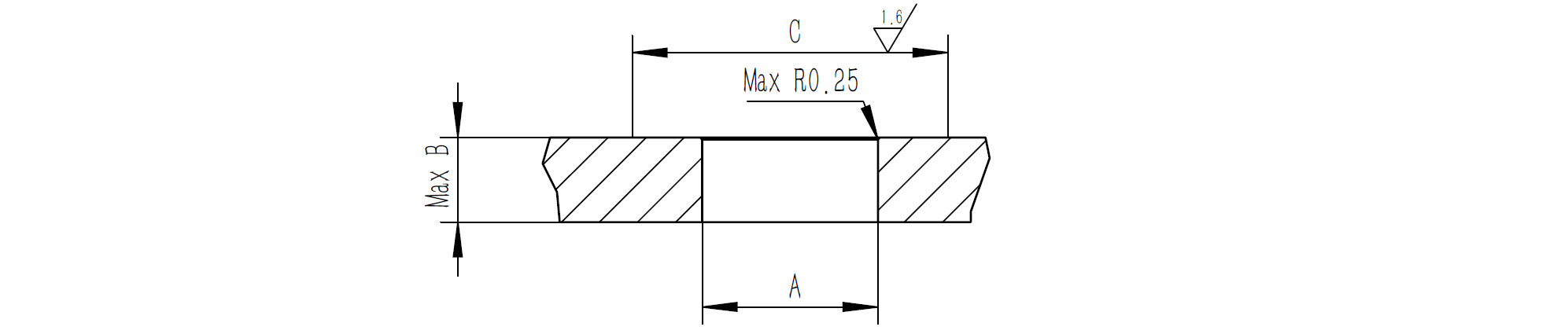

Wiring Definition for M10 Female Plug

3pin M10 female plug: 1-RED 2-YELLOW 3-BLACK

6pin M10 female plug: 1-RED 2-YELLOW 3-BLACK 4-GREEN 5-WHITE 6-BLUE

3pin female plug core specification: ul1332 3×16AWG

6pin female plug core specification: ul1332 3×16AWG+3×24AWG

Cable rated voltage: 300V

Installation effect photo:

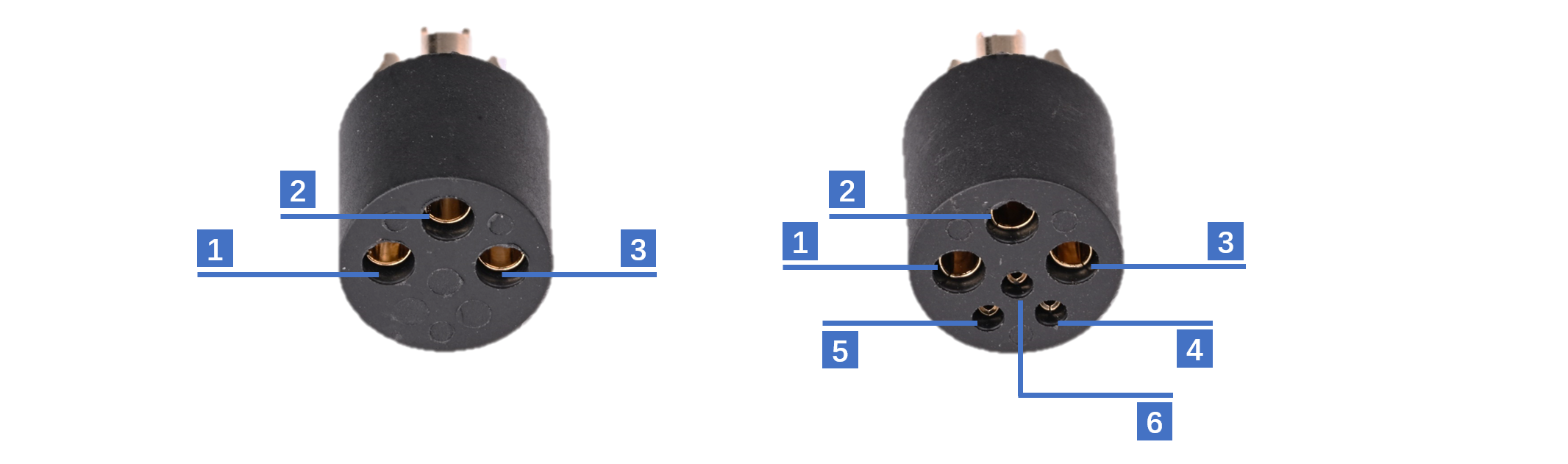

Guides:

● What are dry mate and wet mate connections?

Dry mate refers to connections that can only be inserted and removed in air. They need to be fully connected to provide waterproofing and ensure the pins are not exposed to water.

For instance, the female plug must be connected to a male cable socket or dummy plug to be waterproof. Similarly, a male plug must connect to a female cable socket or dummy plug for waterproofing.

● How do they differ from traditional rubber-sealed connectors?

They allow for self-assembly of wiring, akin to waterproof aviation plugs suitable for deep water.

● What tools and materials are needed for assembly?

1. Compatible cables; 2. Soldering iron; 3. Wire strippers; 4. Isopropyl alcohol and lint-free cloth; 5. Epoxy resin or other sealing adhesives ect.

● Which factors affect waterproofing depth during assembly?

1. Type of adhesive used; 2. Material of cables used; 3. Quality of cleanliness

● What factors affect waterproof performance after assembly?

1. Surface condition of sealing ring contact area (wear or scratches); 2. Aging or damage of sealing ring; 3. Quality of connection

● Why are the connectors very astringent and difficult to plug?

Dow Corning DC111 grease is recommended if no grease is available on the O-ring.

Contact: Miss.Huang

Phone: 18680379366

E-mail: kim@subff.cn

Whatsapp:whatsapp

Add: 6F No3.Building Chuangxinghong Industrial Park Sightseeing Road Fucheng Street Longhua District Shenzhen City, China

We chat